al fianco del cliente per il guidaggio migliore,

Soluzioni made in E.N.S.

ENS produce elementi di guida normalizzati e speciali per stampi plastica, lamiera, pressofusione e per applicazioni industriali.

Sorprende per dinamismo, capacità produttiva e personalizzazioni.

Che siano a magazzino o realizzati su disegno del cliente, i prodotti ENS sono sempre una guida sicura.

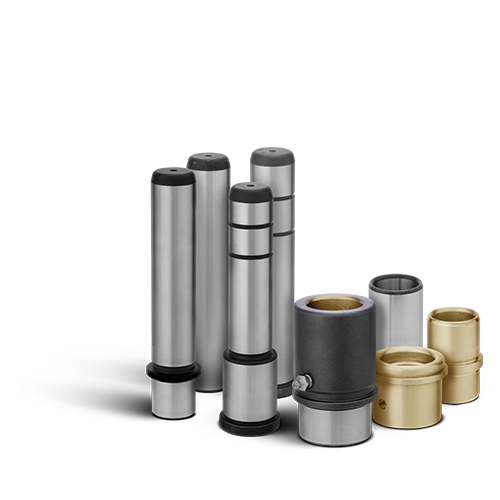

Le 5 famiglie di guidaggi standard a catalogo sono ideali per la soddisfazione di ogni esigenza dalla più semplice alla più gravosa.

Cataloghi

Tutti i nostri componenti a magazzino divisi per serie, pronti per la consultazione e da ordinare.

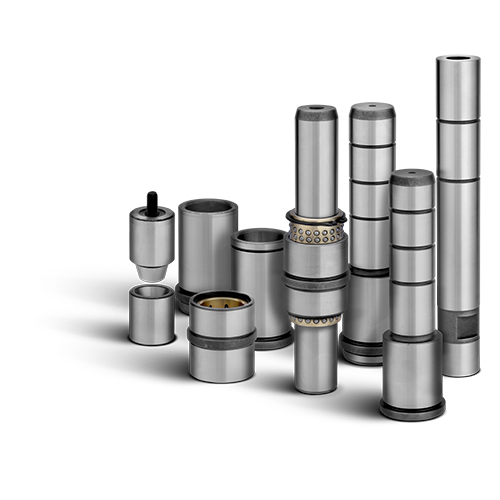

Una storia di sfide e traguardi

Siamo nati per accettare le sfide, ancor più se sono ambiziose e impegnative. Abbiamo continuato a crescere, fare esperienza e adottare tecnologie più avanzate per realizzare richieste fuori dallo standard.

Diventare leader nel nostro settore vuol dire esserci sempre, riuscire a comprendere le esigenze del cliente e tradurle in realtà insieme a lui.

Sorprendere e farsi riconoscere – in Italia e all’estero.

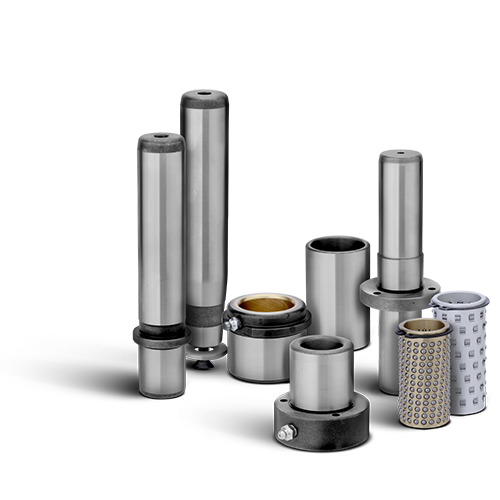

Italia

Italia

Euro

Euro

Iso

Iso

Auto

Auto

Custom

Custom